About Six SigmaLearn More

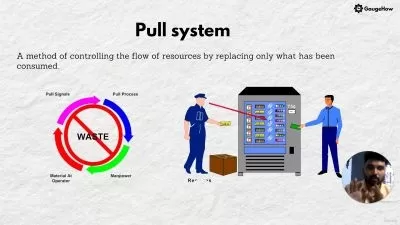

Six Sigma is a structured process implemented by businesses to streamline operations and management better. By reducing waste, whether time, workforce, or materials, Six Sigma tools help minimize output costs, maximizing revenue. Udemy offers a range of Six Sigma courses that can teach you the top down processes and strategies for optimizing operations for any organization.

Sort by:

Sorting

The newest

Most visited

Course time

Subtitle

Frequently asked questions about Six Sigma

Six Sigma is a process improvement methodology that is very popular in manufacturing settings. It is used to ensure the best quality possible with the fewest defects and reworks required. The standard for Six Sigma is that 99.99966% of products created (usually tangible products or parts) should be completely free of defects. Six Sigma seeks to find the most efficient and cost-effective ways to manufacture items or conduct processes. It has many standards and methods of doing work that is consistent and can be replicated every time a process or function is performed. In manufacturing, it is often used to solve failures and identify root causes so that corrective action can be implemented immediately.

Six Sigma is organized similarly to martial arts. Different levels are referenced by different belts, as in Judo. Practitioners range from Green Belts to Champions. The most common are White, Yellow, Green, Black, and Master Black Belts, although there are also options specific to healthcare and data analytics, to name a few. Six Sigma is certified by several universities and other bodies, and ASQ or IASSC are among the most recognized credentialing bodies, although there is no official certification body. Many organizations offer their own version of Six Sigma certification, and there are versions tailored to specific priorities, including the popular Lean Six Sigma.

Six Sigma is hugely popular in the manufacturing sector, though it is also used in healthcare, engineering, construction, finance, and supply chain management. Even in settings that may not completely rely on Six Sigma, there are problem-solving and quality assurance methods within Six Sigma (such as the 5 Whys) that can be helpful in virtually any setting. Much of Six Sigma involves problem-solving, which is a universal skillset. It also helps to sharpen the ability to streamline and eliminate waste in processes, saving organizations time, money, and other resources.

Skills needed before learning Six Sigma include attention to detail, analytical abilities, strategic thinking, and strong verbal and written communication. Six Sigma requires an ability to observe and understand current conditions and to find ways to bridge the gap between these and the ultimate standard. Six Sigma teaches students how to identify the root causes of issues and waste and follow a consistent methodology to address them. This includes gathering the necessary data, forming the right teams, and identifying corrective actions that can be immediately implemented. Time is often of the essence, and many of the problems addressed require quick solutions.